ProCut Guillotine backgauge Control kits

for the printing and sheet metal industries

The PROCUT System is a high precision Guillotine Backgauge Positioning System that can be installed in most industrial paper or metal cutting guillotines. Using our own control systems with their years of proven history for accuracy and repeatability. ProCut can be supplied either as a complete system or as parts as needed

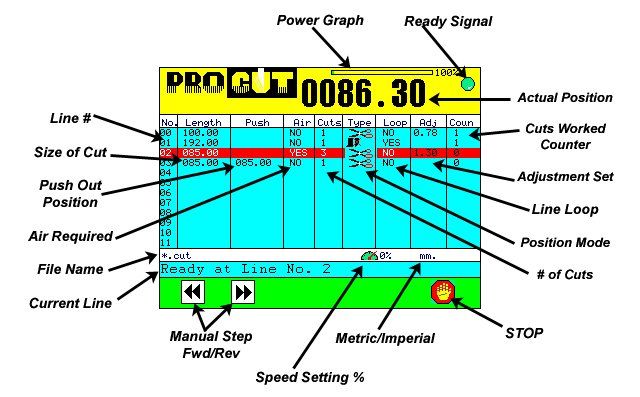

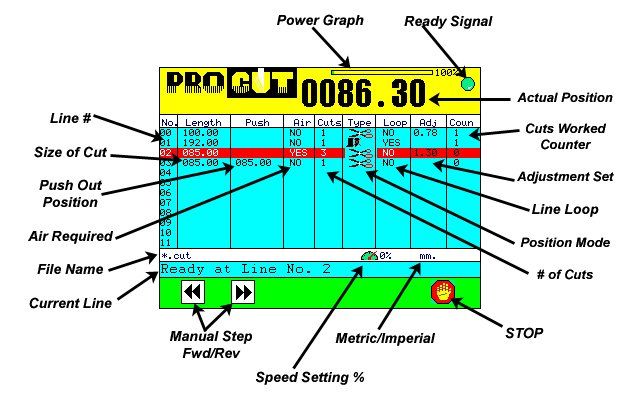

Read more about ProCut's featuresThe PMC4 motion controller is used in many applications, one if them is ProCut. ProCut is an application designed for paper and metal cutting guillotines, it allows the operator to enter a cutting list via user friendly menus. ProCut has automatic features that make cutting lables and strips easy and quick to use, via dedicated menus.

- Rapid return on investment

- Improves productivity and quality

- Reduction of scrap due to the precision ProCut

- ProCut is easy to use and install

- Improves productivity and quality

- Strip and label menus with optimization

- Maintenance planning menu

For example please see the edit create screen as shown below:

Choice of Procut kits for the machine's existing motor, DC or brushless servo motors

Basic Inverter backgauge retrofit kit

The basic system uses the machine's original motor which is controlled by a flux vector inverter. Inverters provide a lower accuracy and performance than servo motors, but at a lower cost. The kit contains a controller, inverter, cables, break out boards, an encoder, Start/Stop buttons, proximity switches and mounting brackets.

Inverter based ProCut Kit: This kit uses the original motor and pulleys, this is more difficult to fit than a servo kit, but more cost effective. This kit requires the included encoder to be installed on the machine lead screw. The retrofitted machine is likely to be a lot more accurate than the original machine, however this requires the installer to adjust the inverter settings correctly.

DC servo ProCut Kit

The DC servo, offers a replacement for the machines existing AC motor and control replacing them with a precision servo. Servos offer high accuracy and good performance. The kit contains a controller, electrical box, DC servo motor, motor mounting bracket, cables, Start/Stop buttons, proximity switches, belts\pulleys and mounting brackets.

ProCut DC Servo Kit: The ProCut DC servo kit includes almost every thing needed to install a ProCut back gauge system on a guillotine, new or old. The controller can be installed in the front of the machine or there is an optional "Pod" that makes mounting the controller simple and easy for the operator with an adjustable mounting arm. The DC servo motors offer very high accuracy and good performance.

Brushless servo ProCut Kit

The Brushless servo, offers a replacement for the machines existing AC motor and control replacing them with a precision AC servo. Brushless Servos offer high accuracy and good performance. The kit contains a controller, electrical box, servo motor, motor mounting bracket, cables, Start/Stop buttons, proximity switches, belts\pulleys and mounting brackets.

Choice of PMC4 motion controllers with 5.7" or 10.4" screen

PMC4 controller with 5.7" screen

The PMC4 is a motion controller with a full PLC. This controller is capable of very high accuracy and when running the ProCut software brings new life to old guillotines and for new machines cost savings, safety, and reliability. Operator comfort is assured because of the clear screen and easy to use compact keypad. The compact size of the PMC4 makes it easy to mount the controller either in or out of the machine front.

PMC4 controller with 10.4" screen

Larger machines need a larger screen and the 10.4" screen is clearly readable even on a large machine. The PMC4 large screen controller has a full QUERTY keypad and built in hand wheel jog encoder to facilitate small cut corrections. This controller is designed to be easy to mount in the front of the machine, the thickness of the controller is around 50mm.

Cables, Sensors, Brackets, Motors

Controller Cables, Sensors and Wiring

ProCut kits come complete with cables, wiring, sensors and sensor mounting brackets. Cables can be ordered in special lengths to suit larger machines or for OEMs

Mechanical components, Pulleys, mounting brackets etc

Part of a complete service is the provision of a fit and forget service. ProCut is supplied with Motor Mounts, belts and pulleys which can be supplied ready machines to suit the client application.

Servo Motors

ProCut is available with a range of servo motor options, there many options including using an existing DC motors, DC servo or Brushless servo

- 600 Watt DC servo (1.7 nM)

- 800 Watt brushless Servo

- 1000 Watt brushless Servo

- 1500 Watt brushless Servo

- 2500 Watt brushless Servo

ProCut Guillotine backgauge software for the printing and sheet metal industries

The PROCUT System is designed to be easy and safe to use, it has two languages English and Spanish, it is easy to enter and save data

- Quick and Easy to use

- High accuracy improves production and quality

- Reduction of scrap due to the precision ProCut

- Internal storage for 1000 files of 32 lines

- Easy to use strip menu

- Easy to use label menu with optimization

- Maintenance planning menu

- Clear easy to use menus in Color

- Manual mode

- Programmable air table and push out modes

Control products from TRM range from temperature control to CNC, General Automation through to motion control

TRM has been designing and manufacturing industrial controllers for more than 22 years. Our controllers can be used in almost any automation process, we get involved in the control of process that involve controlling Motion, Current, Voltage, Temperature. Our standard controllers include a digital recorder that can be set up with up to 8 channels. We make interface boards which include inputs for thermocouples, platinum resistance, load cell, TTL digital there are also 0 to 20 milliamp. Weather you are a OEM, machine renovator, scientific instrument company or you want to automate, we can help! Please call us.

24/7 Service on all Industrial Production Equipment. | Maintenance Contracts Available. | Full Service Maintenance Company.

20-year Safety Record | Equipment Safety Standard Consulting | Fully Insured

Contact Us Today!

Contact Us

We will get back to you as soon as possible

Please try again later